JD Electric's Forged Iron/Aluminium Socket End Fitting

This Forged Iron/Aluminium Socket is meticulously crafted for integration into power equipment. Its production necessitates accurate forging procedures and stringent quality supervision. The caliber of the socket is a testament to the manufacturer's proficiency and dedication to quality. It is accompanied by pertinent quality assurance credentials.

In operation, it pairs with the Forged Iron/Aluminium Ball, creating a dependable connection. It showcases remarkable mechanical attributes, including robust strength and excellent abrasion resistance, allowing it to withstand the mechanical forces and oscillations in power transmission. The material choice, whether iron or aluminium, is tailored to meet diverse application demands and environmental circumstances, enhancing the overall sturdiness and functionality of the power apparatus.

Application:

It is mainly employed at the terminals of composite insulators and similar electrical components. Its chief objective is to establish a firm and conductive link, which is vital for the effective conveyance of electrical energy and the safeguarding of the power grid against overvoltage and other malfunctions.

Standards:

IEC 61466-1:2016

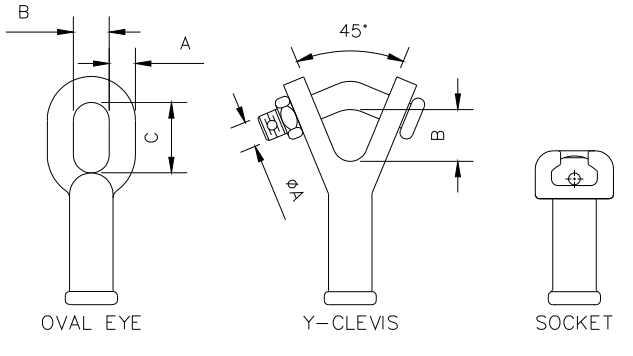

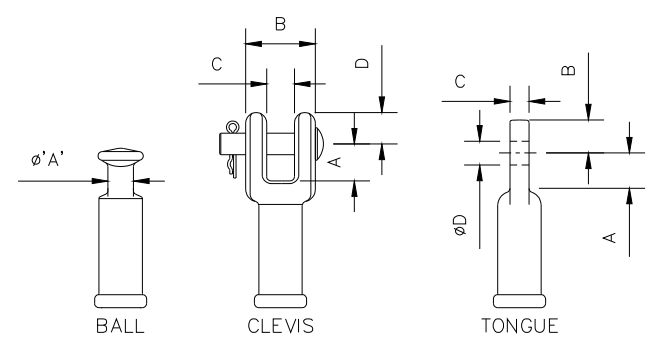

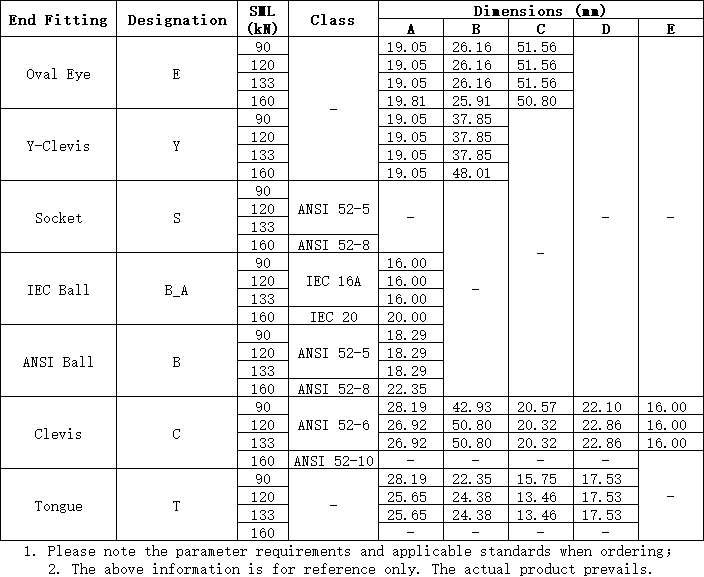

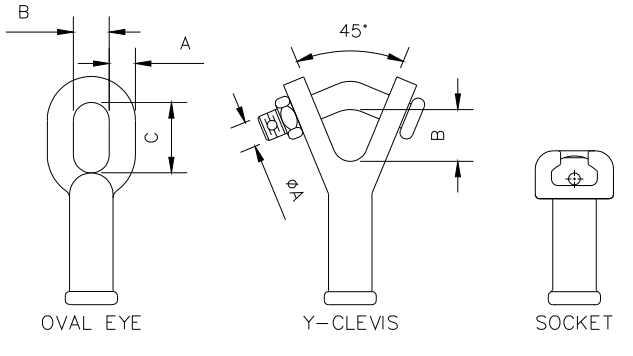

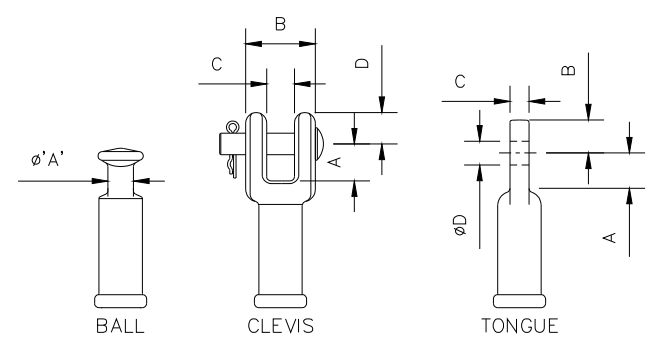

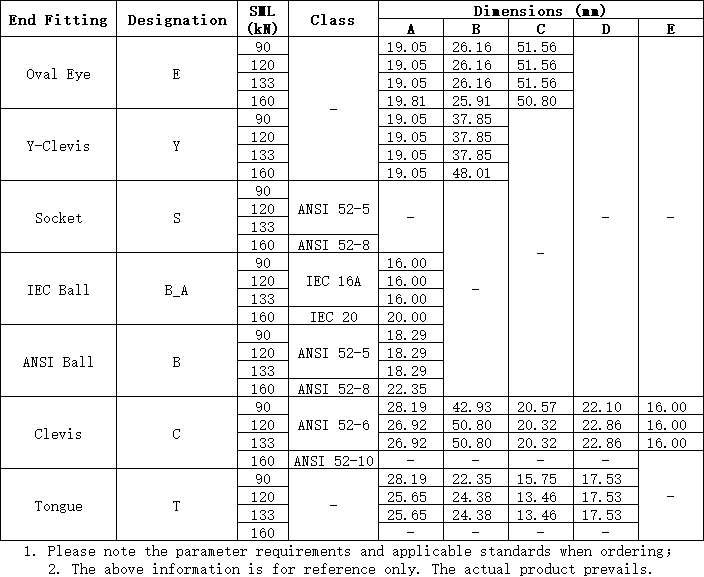

Specifications:

Features:

It can cope with the challenges of power transmission, enduring substantial mechanical loads, thereby safeguarding the connection's integrity and reducing the likelihood of component breakdown.

The selection between forged iron and aluminium is determined by specific application requirements, offering adaptability in design and performance. Iron provides enhanced strength and longevity, whereas aluminium is lighter and exhibits superior corrosion resistance in certain settings.

It is engineered to fit accurately with the corresponding Forged Iron/Aluminium Ball, ensuring a tight and reliable connection. This compatibility is essential for upholding the electrical and mechanical stability of the power equipment.

It is capable of withstanding a broad spectrum of environmental conditions, such as temperature variations, moisture, and exposure to contaminants, and continues to operate reliably over an extended duration, minimizing the need for frequent replacements and upkeep.