This 25kV/27.5kV Double-insulated Cantilever Insulator is purpose-designed for the specific 25kV/27.5kV voltage grade in the railway context. When the railway power supply system is active, it not only isolates the electrical conductors from the cantilever's support framework to avoid electrical leakage but also offers an elevated degree of insulation protection for the entire contact network. In addition to the fundamental insulation task, it must conform to the particular technical stipulations of the railway. For instance, it has to endure the constant vibrations due to passing trains and sustain stable performance within the intricate electromagnetic surroundings along the railway track. During the design and development process, meticulous attention is given to aspects like material compatibility and structural integrity to guarantee its suitability for railway applications. Rigorous quality control measures are implemented during production to ensure each insulator meets the required specifications.

Distinguishing it from the single-insulated variant is a unique design characteristic. At the base of its silicone rubber component, there is a pre-designed wire groove situated between the second last and the final umbrella skirts. After installation, a wire can be inserted into this groove. In case of a discharge, the wire in the groove can short-circuit the insulator's base, redirecting the current and thereby protecting the insulator from total breakdown.

Compared with the insulators used in power grid systems, there are some differences in the insulators for electrified railways in terms of materials, design, and application. For instance, Cantilever Insulators are similar to the Insulated Cross-arms in power systems. However, Cantilever Insulators need to be installed between the Cantilevers with a flexible buffer structure and the vertical poles, so as to prevent the strong wind and high-frequency vibrations generated when trains pass at high speeds from directly acting on the Cantilever Insulators through the contact network wires, thus extending the service life of the Cantilever Insulators. Cantilever Insulators are required to bear the weight of the contact network wires and the Cantilevers. Hence, Cantilever Insulators should use thicker core rods and more durable forged fittings.

Standards:

IEC 62621-2011; TB/T 3199.2-2018; Q/CR 549-2016

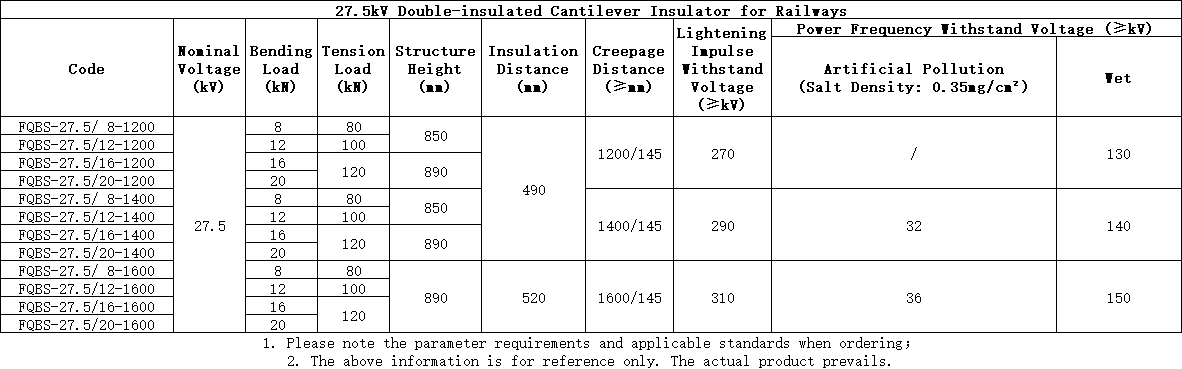

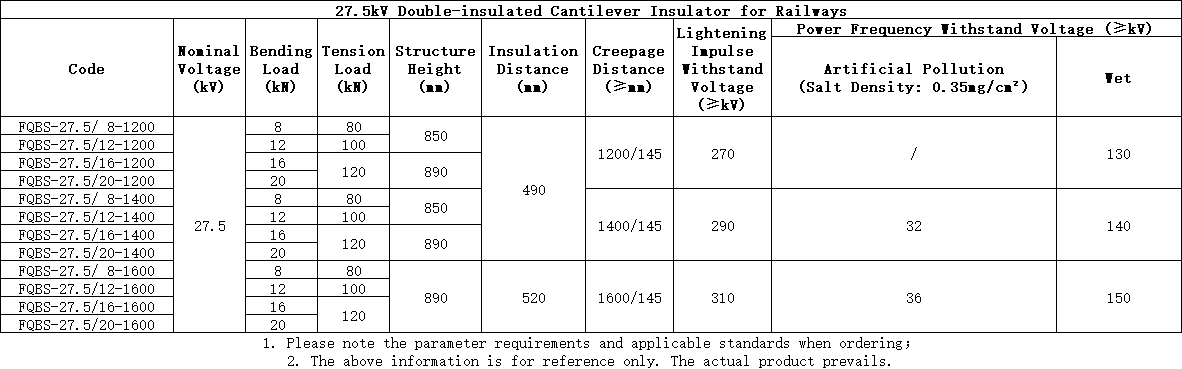

Specifications:

Application:

It is mainly employed on the cantilever of the electrified railway contact network. Its principal function is to support the electrical conductors and maintain top-notch electrical insulation, which is crucial for the stable power supply and the safe running of trains.

Features:

● High Reliability:

Meeting the exacting standards of the railway domain, it can function consistently over an extended period, minimizing maintenance requirements and ensuring the smooth progress of railway operations.

● Railway-adapted Design:

Its architecture and material choices are optimized in line with the railway environment's traits, making it more resilient to the challenges presented by railway operations than regular power system insulators.

● Superior Anti-pollution Ability:

Given the diverse pollutants present along the railway, it has an efficient anti-pollution design to maintain its insulation performance, ensuring the safety of the railway power supply network.

● Powerful Vibration Tolerance:

With outstanding resistance to vibration, it can proficiently handle the vibrations caused by passing trains and preserve its position and insulation function on the cantilever.