35kV Composite Post Insulator

This insulator is carefully designed for the operation rod of disconnectors. To make it, advanced CAD/CAM design software is used to create detailed design plans. Highly automated production lines are used to ensure precision and consistency. Sophisticated molding and curing methods are also used to improve the material's quality. A manufacturer's ability to produce this insulator shows its high - level technical skills and production capabilities. Stringent in - house and external inspection procedures are carried out. It gets multiple certifications that show it meets both international and domestic standards.

During operation, this insulator has two main jobs. It separates conductors electrically and withstands different dynamic forces. It has strong anti - torsion and anti - bending abilities. Also, it shows excellent anti - fatigue features. This helps it endure the repeated mechanical stress from frequent disconnector operations. Because of its role in the operation rod of disconnectors, micron - level dimensional accuracy is necessary. The upper and lower fitting interfaces must be aligned very precisely. The core rod's straightness must meet a leading - industry standard. If there is any deviation, it may cause misalignment during disconnector operations. This can lead to arcing, uneven wear, and in serious cases, grid disruptions. Electrically, it uses advanced composite materials with high breakdown voltage and low dielectric loss. So, it can perform stably even under transient over - voltage conditions. Environmentally, it is designed to resist the harmful effects of salt - rich air in coastal areas, the abrasive nature of sand - filled winds in desert regions, and the chemical contaminants in industrial zones.

Standards:

IEC 61952-2008; IEC 62231; ANSI C29.18

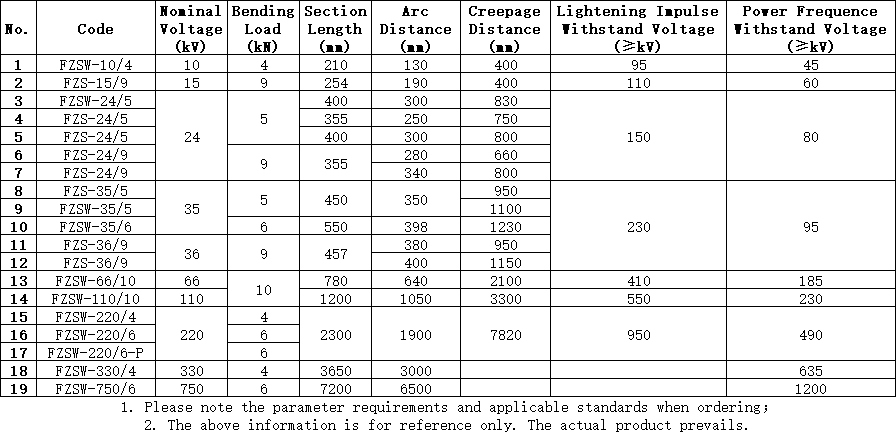

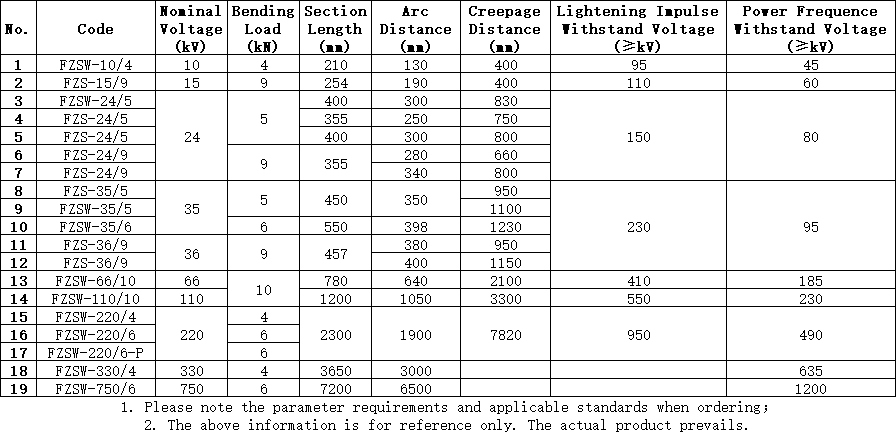

Specifications:

Application:

Mainly, it is used in the 35kV power grid. It is firmly attached to the operation rod of disconnectors. Its main function is to provide stable electrical insulation and strong mechanical support. By doing this, it not only keeps disconnector operations safe but also helps with the overall stability of the power grid. It plays a big role in power distribution from substations to end - user connections.

Features:

It is designed to meet the strict requirements of the 35kV grid and the unique stress of the operation rod of disconnectors. It can operate steadily for a long time. This long - term reliability reduces the need for frequent replacements. So, it cuts operational costs and ensures an uninterrupted power supply.

Using finite - element analysis and material science advancements, its structure and material are adjusted precisely to fit the 35kV voltage environment and the mechanical needs of the operation rod. This makes it better at handling complex electrical and mechanical stressors than regular insulators.

It has hydrophobic coatings, corrosion - resistant alloys, and UV - resistant materials. So, it can adapt to different environmental conditions. Whether it's very cold in the Arctic or very hot in the tropics, it can keep its integrity and performance.

Its design can fit different installation angles, vibration levels, and electrical load conditions. It can fit into various grid configurations smoothly. Especially for those with high - performance needs for the operation rod of disconnectors, it can perform consistently in different operating situations.