110kV Composite Post Insulator

This 110kV composite post insulator is crafted for high-voltage grid utilization. Its fabrication demands precise engineering, state-of-the-art manufacturing tools, and refined production techniques. The possession of the capacity to manufacture such insulators is a testament to a manufacturer's proficiency. The insulator is accompanied by relevant quality inspection approvals.

During its operation, it segregates conductors and endures substantial loads, particularly those related to torsion and flexural forces. The flange configuration guarantees a sturdy attachment with associated parts. It exhibits outstanding electrical insulation and robust mechanical properties, resists environmental adversities, and is vital in 110kV power transmission, especially in regions with specific environmental conditions.

Standards:

IEC 61952-2008; IEC 62231; ANSI C29.18

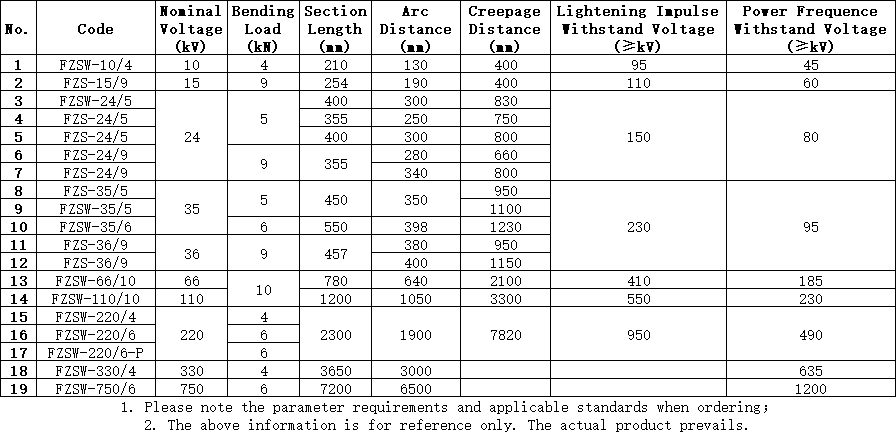

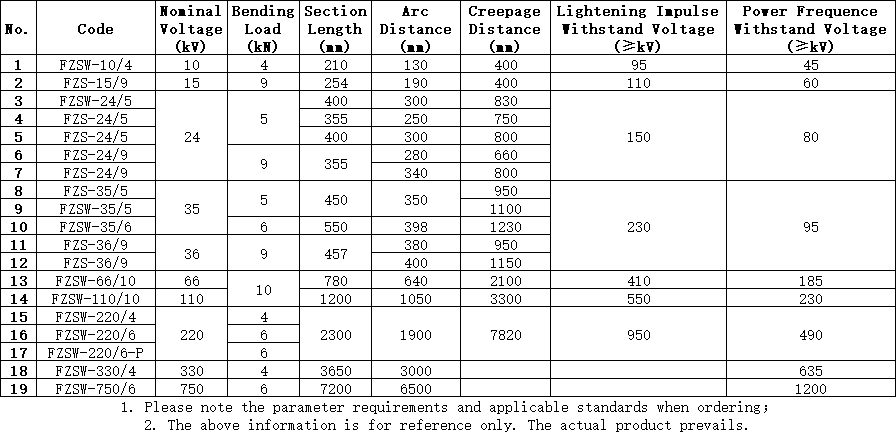

Specifications:

Application:

It is mainly deployed to support conductors in the 110kV power grid. Its core task is to supply stable electrical insulation and reliable mechanical support, which is essential for the unbroken power supply and the grid's integrity.

Features:

● Prolonged Service Life:

Meeting the demands of the 110kV grid, it can function dependably over an extended period, curtailing the need for frequent maintenance and facilitating efficient power conveyance.

● Customized Design for 110kV Insulation:

Its structural and material aspects are fine-tuned to manage 110kV voltage levels. It copes with the particular insulation requisites in a 110kV power grid more proficiently than numerous other insulators.

● Resilient Against Environmental Factors:

Taking into account diverse environmental challenges in different locales, it has appropriate countermeasures to withstand these impacts and keep the power grid operating without interruption.

● Versatile Adaptability:

With excellent performance in tolerating various forces and environmental fluctuations, it can sustain its insulating and supporting functions for conductors under a broad spectrum of operating scenarios, especially those demanding good anti-torsion and anti-bending capabilities.