Brief Introduction of composite long-rod insulators

The emergence of composite long-rod insulators is attributed to the progress of fiber-reinforced composite materials. FRP core rods, in particular, can be fabricated into a single continuous 20m-long piece, a feat unattainable by traditional porcelain or glass insulators. For low and medium-voltage grids, the length of composite long-rod insulators usually ranges from 10 to 100cm, while in ultra-high voltage grid systems, it can extend up to 10m.

These insulators are mainly utilized in suspension insulator strings for straight line support and tension insulator strings of elevated and terminal towers. They are also applicable at jumpers or the entrances of outdoor substations. Given that composite insulators are significantly lighter than traditional ones (at 400kV, their weight is merely about 10% of that of porcelain long-rod insulators), they are highly favored in the design of special structure towers like catenary suspension towers in Canada, South Africa, and Argentina, as well as floating terminal towers designed to reduce tower height.

This 330kV composite long rod insulator is specifically designed for the corresponding high-voltage grid environment. Producing it, which involves a high voltage and a relatively long structural height, demands ingenious design concepts, advanced manufacturing equipment, and mature production processes. It's worth noting that JD Electric's 10 - 500kV long rod insulators (Deadend / Suspension Insulators) have already obtained the inspection reports from the international authoritative institution XIHARI, demonstrating their high quality.

Know More Details about XIHARI Test Reports,

Click: JD-Electric Got XIHARI Test Reports for 10 - 500kV Long Rod Insulators

During operation, this insulator offers effective insulation for conductors and endures diverse loads such as those from wind and ice. Its performance is enhanced via optimized structural design, like adjusting material composition for better overall strength. The precisely crafted ball and socket end fittings ensure a stable yet flexible connection with conductors, facilitating adaptation to conductor movements. With fine resistance to environmental factors, it excels in high-voltage long-distance power transmission and harsh climates, often surpassing conventional insulation options.

Standards:

IEC 61109-2008; ANSI C29.12

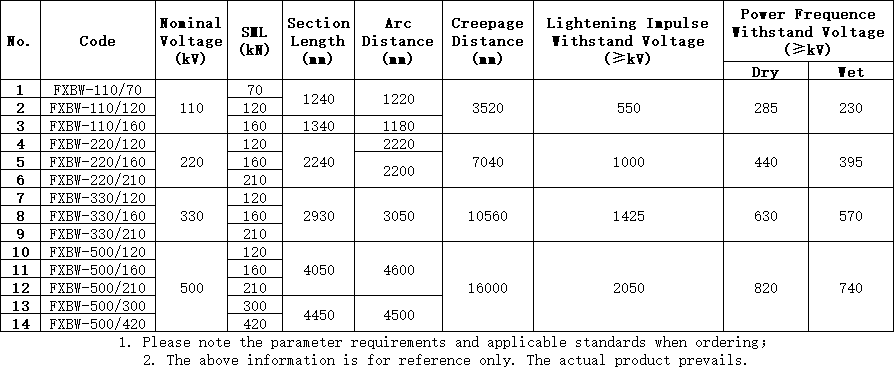

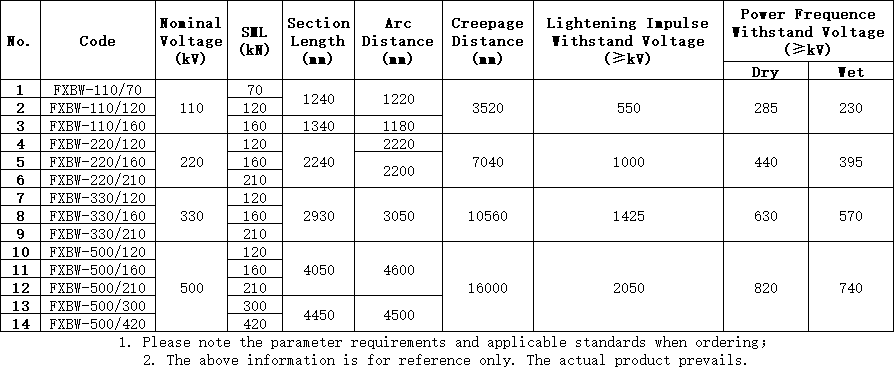

Specifications:

Application:

The 330kV Composite Long Rod Insulator with Ball and Socket End Fittings is a crucial element in the power grid. It is predominantly installed along conductors in high-voltage and long-distance transmission lines. By providing stable electrical insulation and mechanical support, it safeguards the integrity of power transmission.

This insulator is essential for maintaining grid stability, ensuring continuous electricity supply, and withstanding the rigors of high-voltage environments. It enables efficient power transfer over extended distances, minimizing power losses and disruptions, and is thus vital for the reliable operation of the entire power grid system.

Features:

● High Reliability:

Designed to meet the exacting demands of the power grid, this insulator exhibits exceptional reliability. It can endure long-term operation without significant degradation, reducing the need for frequent maintenance. Its robust construction and quality materials ensure consistent performance, allowing for seamless power transmission and minimizing the risk of outages. This reliability is crucial in maintaining the uninterrupted flow of electricity and the overall stability of the power grid.

● Special Design for High-Voltage Application:

The 330kV Composite Long Rod Insulator features a meticulously engineered structure and carefully selected materials. Optimized for withstanding 330kV, it addresses the unique challenges of high-voltage insulation. Unlike standard insulators, it incorporates advanced design elements to handle the intense electrical stresses. This specialized design ensures reliable insulation performance, enhancing the safety and efficiency of high-voltage power transmission and protecting the grid from potential breakdowns.

● Good Resistance to Environmental Influences:

To combat various environmental challenges, this insulator is equipped with effective protective features. It can withstand extreme temperatures, humidity, and pollution, ensuring stable operation in diverse climates. Its anti-corrosion and anti-fouling properties prevent degradation over time, maintaining its insulating capabilities. This resilience against environmental factors is essential for reliable power grid performance, especially in regions with harsh or fluctuating conditions.

● Strong Adaptability to Multiple Conditions:

With outstanding adaptability, this insulator performs well under a wide range of operating conditions. It can handle different external forces, such as wind and ice loads, without compromising its insulation or support functions. Whether in normal or extreme circumstances, it remains stable and effective, providing consistent protection and support to conductors. This versatility makes it suitable for various power grid applications, enhancing grid flexibility and reliability.

● Lightweight Advantage:

Weighing significantly less than traditional insulators, this 330kV Composite Long Rod Insulator offers a distinct advantage. At 330kV, it is much lighter than porcelain or glass counterparts, reducing the load on supporting structures. This lightweight characteristic simplifies installation and maintenance, and also allows for the use in special structure towers. It enables more efficient tower design and construction, potentially reducing costs and improving overall grid aesthetics.

● Enhanced Structural Integrity:

The insulator's structural design is optimized for enhanced integrity. The use of fiber-reinforced composite materials in the FRP core rod provides high tensile strength and flexibility. The precisely crafted ball and socket end fittings not only ensure a secure connection but also allow for some movement to accommodate conductor vibrations and thermal expansion. This combination of strong core and flexible fittings results in a durable and reliable insulator that can withstand the mechanical stresses of high-voltage power transmission.