Brief Introduction of 220kV Composite Long Rod Insulator

This 220kV composite long rod insulator is designed for high-voltage grids. Its production needs creative design, advanced equipment, and refined processes. JD Electric's 10 - 500kV Long Rod Insulator (Deadend / Suspension Insulators) have XIHARI reports.

Know More Details about XIHARI Test Reports,

Click: JD-Electric Got XIHARI Test Reports for 10 - 500kV Long Rod Insulators

Composite long-rod insulators are often used as suspension insulators or tension insulators, so the tensile resistance performance is of particular concern. The mechanical properties of composite insulators are mainly related to the core rod, fittings, and their assembly methods.

The tensile load of FRP rods is mainly borne by nearly one million glass fibers (for example, a core rod with a diameter of 16mm has approximately 80,000 single glass fibers in its cross-section). Therefore, the selection of core rod raw materials and the extrusion molding process play a decisive role in quality.

According to the experimental results of Claude de Tourreil's team at the Hydro-Québec Research Institute, forged fittings perform better than cast fittings, and crimped fittings exhibit more excellent tensile properties than wedge-shaped and tapered fittings.

JD Electric purchases high-quality glass fibers from the world's leading glass fiber manufacturers and manufactures high-tensile-strength core rods independently by relying on its own mature core rod manufacturing process. At the same time, JD Electric independently conducts forging and machining of fittings to produce high-strength and low-tolerance fittings. For high-load products, experienced workers with more than 5 years of crimping experience strictly execute the secondary crimping process in accordance with the standard operating procedures to ensure the reliable connection between the core rod and the fittings. The finished products will be subjected to tensile tests one by one to ensure that each product can operate safely in the global power system.

Standards:

IEC 61109-2008; ANSI C29.12

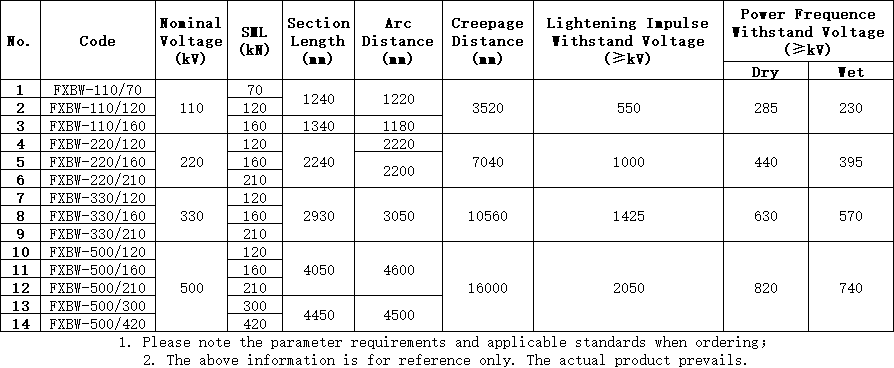

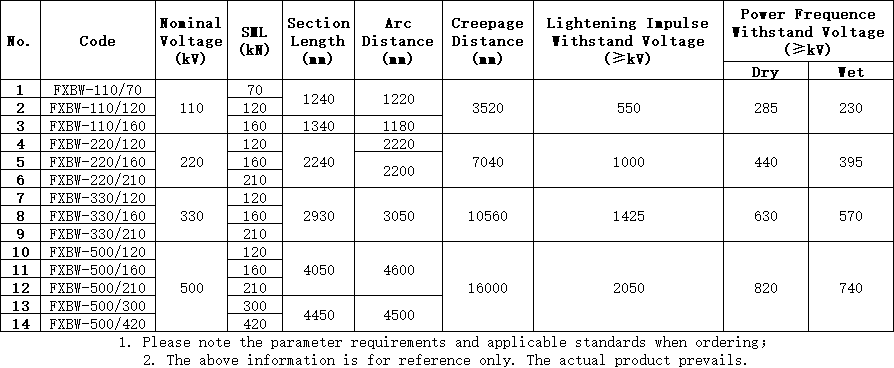

Specifications:

Application:

The 220kV Composite Long Rod Insulator with Ball and Socket End Fittings is an essential component within the power grid infrastructure. It is principally deployed along the conductors of high-voltage and moderately long-distance transmission lines. By providing stable electrical insulation and robust mechanical support, it serves as a safeguard for the conductors. This is not only crucial for maintaining the stable and efficient operation of the power grid but also for ensuring the continuous and reliable supply of electricity to end-users. It effectively mitigates the risks of power failures and disruptions, thereby playing a significant role in power transmission and distribution networks.

Features:

● High Reliability:

Tailored to meet the stringent requirements of the power grid, this insulator demonstrates remarkable reliability. It is engineered to operate continuously and stably over an extended tenure, significantly minimizing the frequency of maintenance interventions. Its durable construction and high-quality materials ensure consistent performance, allowing for the seamless and uninterrupted flow of power, and safeguarding the integrity of the power transmission process.

● Special Design for High-Voltage Usage:

The 220kV Composite Long Rod Insulator features a meticulously crafted structure and precisely selected materials. The design is optimized to endure the specific challenges posed by 220kV voltage levels. Unlike conventional insulators, it incorporates advanced technological features to address the unique demands of high-voltage insulation, ensuring maximum safety and efficiency in power transmission.

● Good Resistance to Environmental Changes:

Anticipating diverse and potentially harsh environmental conditions, this insulator is equipped with effective protective mechanisms. It can withstand extreme temperatures, corrosive agents, and pollutants, thereby ensuring the uninterrupted operation of the power grid. Its robust design and anti-corrosion properties enable it to maintain optimal performance, even in the face of adverse environmental factors.

● Strong Adaptability to Varied Conditions:

With exceptional adaptability, this insulator can handle a wide spectrum of external forces and environmental fluctuations. Whether subjected to strong winds, heavy ice loads, or temperature variations, it retains its insulation and support functions. This versatility makes it suitable for a variety of operating conditions, enhancing the overall resilience and flexibility of the power grid.

● Superior Tensile Resistance:

As composite long-rod insulators are often used as suspension or tension insulators, tensile resistance is a critical factor. The 220kV insulator excels in this aspect. It is fabricated with high-tensile-strength core rods made from top-quality glass fibers sourced from global leaders. Coupled with precisely forged and machined fittings and a strict secondary crimping process for high-load products, it can withstand significant tensile forces, ensuring reliable connections and safe operation in the power system.

● Quality Assurance and Testing:

JD Electric places great emphasis on quality. The insulator undergoes a comprehensive manufacturing process, including the use of advanced equipment and refined techniques. To guarantee its performance, each finished product is subjected to individual tensile tests. This rigorous quality control protocol ensures that every 220kV Composite Long Rod Insulator meets the highest standards and can operate safely and effectively in the global power grid, providing customers with peace of mind and reliable power transmission solutions.