The Forged Iron/Aluminium Tongue is meticulously designed for use in power transmission applications. Its manufacturing process involves precise techniques and strict quality management. The quality of the tongue is a manifestation of the manufacturer's proficiency and commitment to quality. It is accompanied by relevant quality certificates.

During operation, it serves as an important connecting element, facilitating the interaction between different parts of the power system with reliability and stability. It possesses excellent mechanical qualities, such as high rigidity and good impact resistance, enabling it to withstand the mechanical forces and dynamic conditions in power transmission. The choice between iron and aluminium materials is based on the specific requirements of the application and the environmental context, enhancing the overall performance and durability of the power system.

Application:

It is widely applied in the connection and interaction of various components in the power transmission network, such as insulators and conductive elements. Its main function is to establish a secure and stable connection, ensuring the efficient transfer of electrical power and the overall safety and reliability of the system.

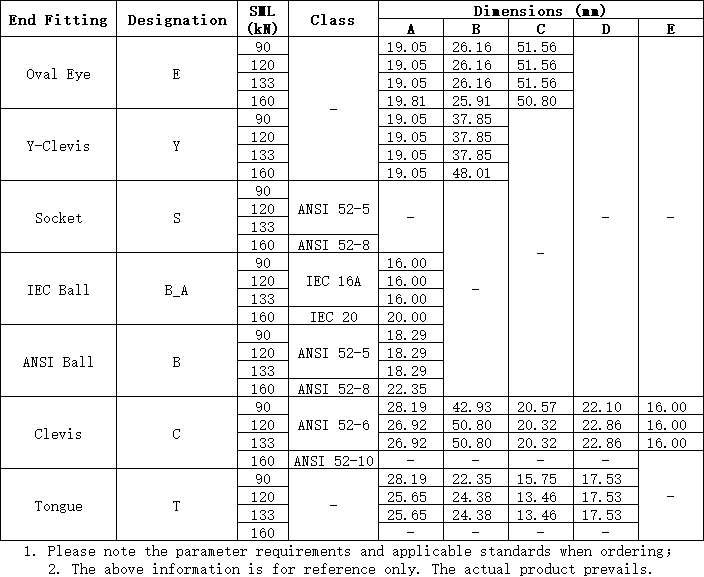

Standards:

IEC 61466-1:2016

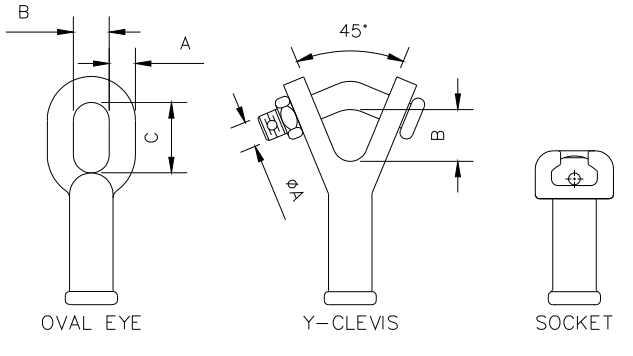

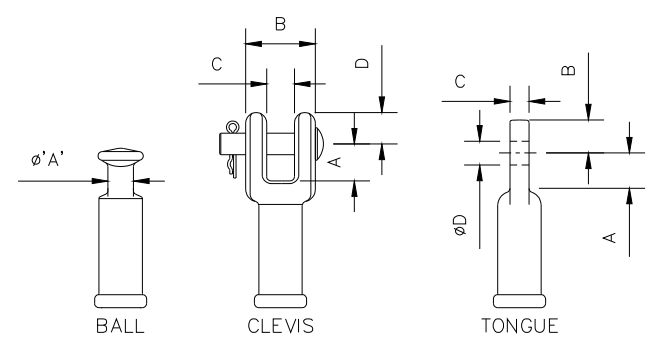

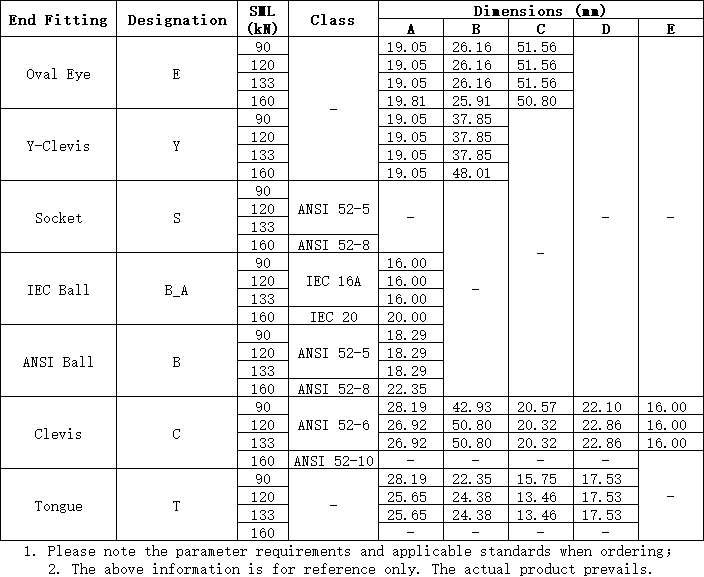

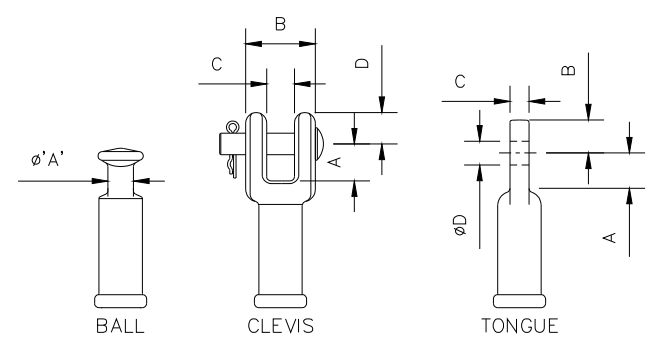

Specifications:

Features:

It can effectively resist the mechanical forces and vibrations in power transmission, ensuring the stability and reliability of the connection. This helps to maintain the structural integrity of the power system and prevent potential failures.

The option of forged iron or aluminium allows for customization based on the application's needs. Iron provides higher rigidity and durability, while aluminium offers a lighter weight and better corrosion resistance in some environments, providing more choices for different installation scenarios.

It is engineered with precise dimensions and tolerances to ensure a proper fit and interaction with the connected components. This precision is essential for maintaining the mechanical and electrical performance of the power system.

It is capable of withstanding various harsh environmental conditions, including temperature variations, humidity, and exposure to corrosive substances. This ensures its long-term reliability and reduces the frequency of maintenance and replacements.