Forged Iron/Aluminium Oval Eye Introduction

The Forged Iron/Aluminium Oval Eye is specifically crafted for power transmission applications. Its production requires precise forging methods and strict quality control. The quality of the oval eye is a reflection of the manufacturer's technical skills and dedication to quality. It comes with relevant quality assurance documents.

During operation, it serves as a key connection and support point, facilitating the interaction between different parts of the power system with stability and reliability. It exhibits excellent mechanical properties, such as high tensile strength and good flexibility, enabling it to withstand the mechanical forces and dynamic changes in power transmission. The selection of iron or aluminium as the material is based on the specific application requirements and environmental conditions, enhancing the overall performance and durability of the power system.

Application:

It is commonly used in the connection and support of various components in the power transmission network, such as insulators and wires. Its main purpose is to provide a secure and stable connection and support, ensuring the smooth flow of electrical power and the overall safety and reliability of the system.

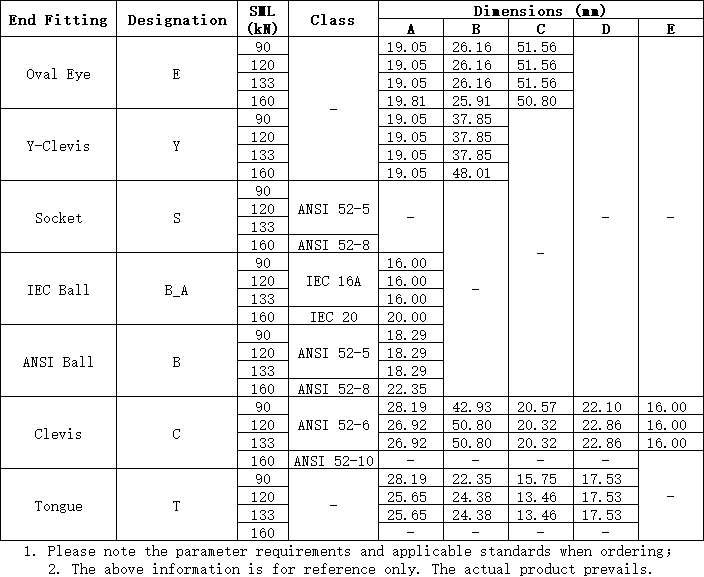

Standards:

IEC 61466-1:2016

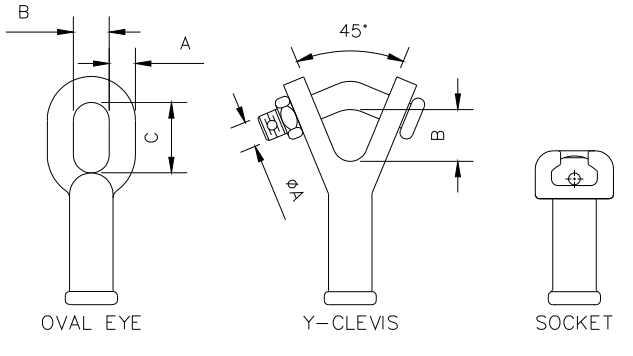

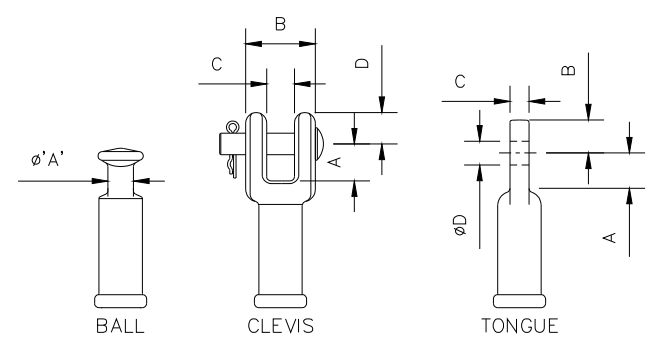

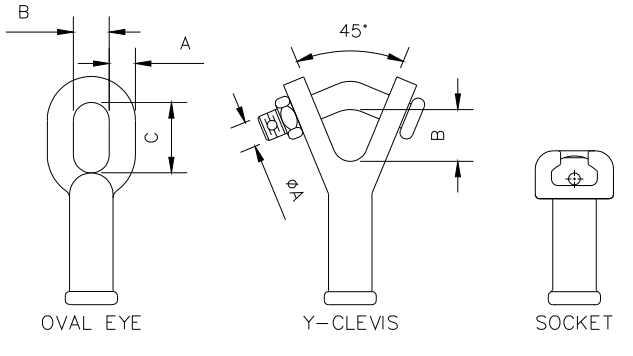

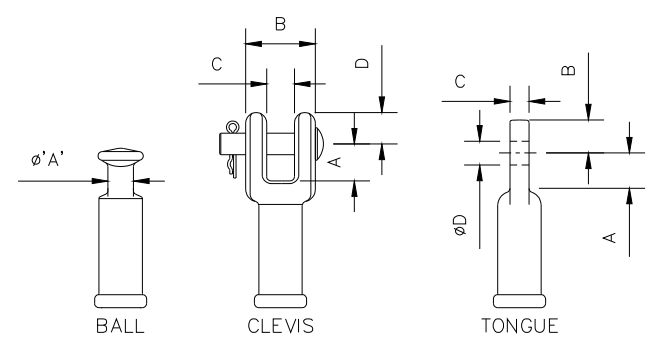

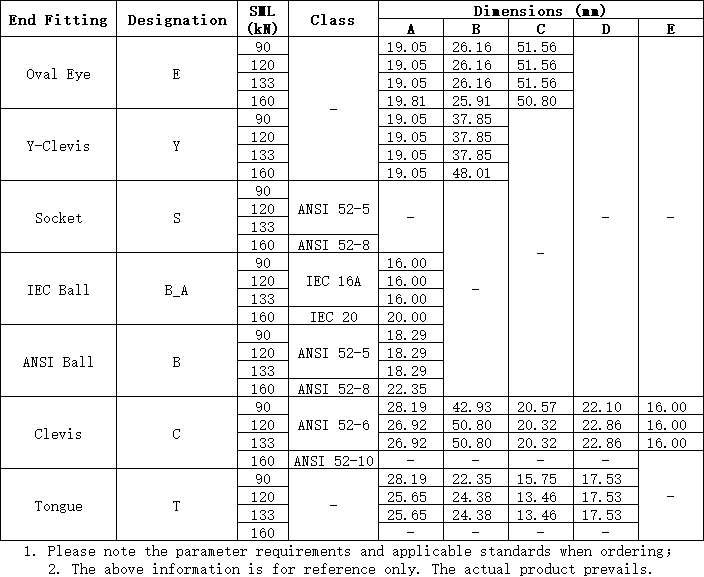

Specifications:

Features:

It can handle the mechanical forces and stresses in power transmission effectively, ensuring the integrity of the connection and support. This helps to prevent failures and ensure the stable operation of the power system.

The choice between forged iron and aluminium offers flexibility to meet different application needs. Iron provides greater strength and durability, while aluminium is lighter and has better corrosion resistance in certain environments, making it suitable for various installation conditions.

It is designed with precise dimensions and shapes to ensure a proper fit and interaction with the connected components. This precision is crucial for maintaining the mechanical and electrical performance of the power system.

It is capable of withstanding a wide range of environmental challenges, such as temperature fluctuations, humidity, and exposure to pollutants. This durability ensures its long-term functionality and reduces the need for frequent maintenance and replacements.